Trafalgar Facades

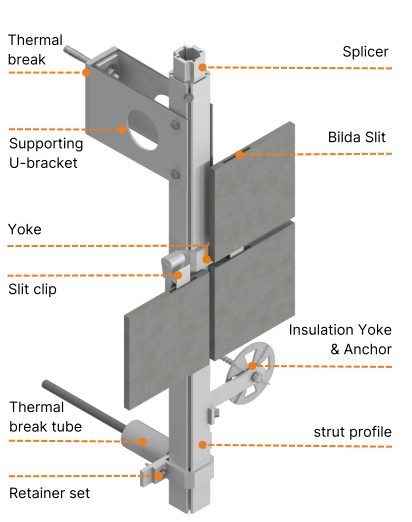

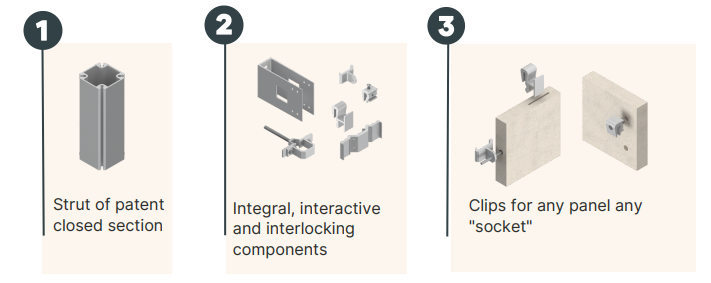

BILDA's system and technology are built upon a foundation of three key innovations: a precisely engineered façade panel slot, simple and interlockable components, and a structurally sound square profile.

BILDA is an innovative system and technology for fixing any cladding and insulation. BILDA provides advantages for all stakeholders in the building envelope process.

This modular facade system that uses precision slots, closed square profiles and simple interlocking connections between all system components. It is low cost, universal, offers quick and convenient assembly (due to its interlocking elements), and is great for complex solutions.

BILDA’s intuitive design ensures swift and effortless assembly. Its self-guiding, interlocking components minimise measurements and installation steps, resulting in rapid construction, reduced errors, and optimal performance. The system’s low learning curve makes it accessible to a wide range of users.

Quick and easy to assemble, the system has a low learning curve. All elements of BILDA are self-guiding, self-aligning and interlocking. This means less measurements and fewer installation steps, and guaranteed coupling of the elements on the building site. The result – rapid assembly, minimised errors, optimal performance and low installation costs.

Versatile and adaptable, the BILDA facade system is designed to accommodate all types of cladding materials, offering a universal solution for any architectural project. From traditional to contemporary, our system seamlessly integrates with various cladding materials, ensuring exceptional performance and aesthetics across the board

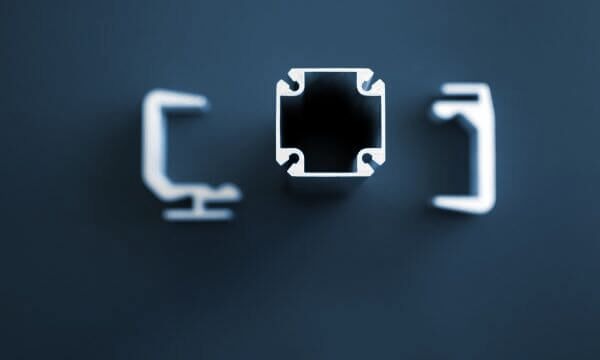

– Forms interlocking connections with other elements through dovetail coupling

– Up to 10 times stronger than a comparable T-section profile

– Makes for a lighter, stronger substructure

Each component of BILDA comprises a part or a contour corresponding to a part of the component it connects with. The revolutionary dual tongue & groove peripheral fastening ensures easy&quick assembly.

The blades of the fixing clips tie back the panels by penetrating the slots. The ‘slot- and-blade’ connection also allows for even distribution of stress from horizontal load.

The precision slot (half-moon shape) is processed with minimum penetration into the panel and ensures a reliable grip of the supporting system components. The slot is easy and inexpensive to make with BILDA stationary slot-milling rig or handheld machines.

Side and rear fixing clips ensure mechanical fixing of:

Side and rear fixing clips ensure mechanical fixing of:

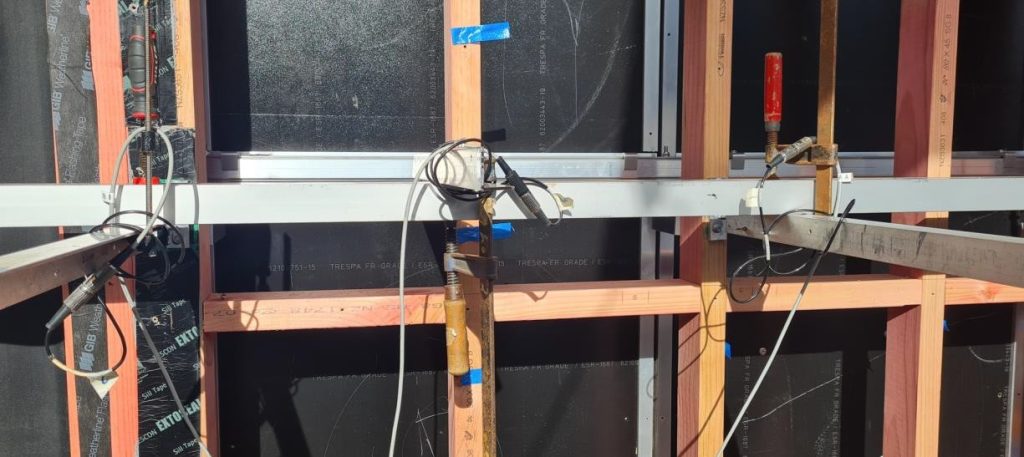

BILDA Facade system was tested under AS/NZS 4284 standard, showing outstanding structiral stability and seismic performance.

Curtain Wall (CW) glazed with stone pilasters of Granite and Limestone Facade Insallation underway